Cooper Hewitt talks to Don Ingber, founding director of the Wyss Institute for Biologically Inspired Engineering at Harvard University, and Joanna Aizenberg, founding core faculty and lead of the Adaptive Material Technologies Platform at the Wyss Institute. The Wyss Institute (founded 2009) has developed a new model for innovation, collaboration, and technology translation within academia, breaking silos to enable collaborations that cross institutional and disciplinary barriers. Wyss faculty and staff engage in high-risk research that leads to transformative breakthroughs for medicine and the environment by combining approaches from the design, art, and technology sectors.

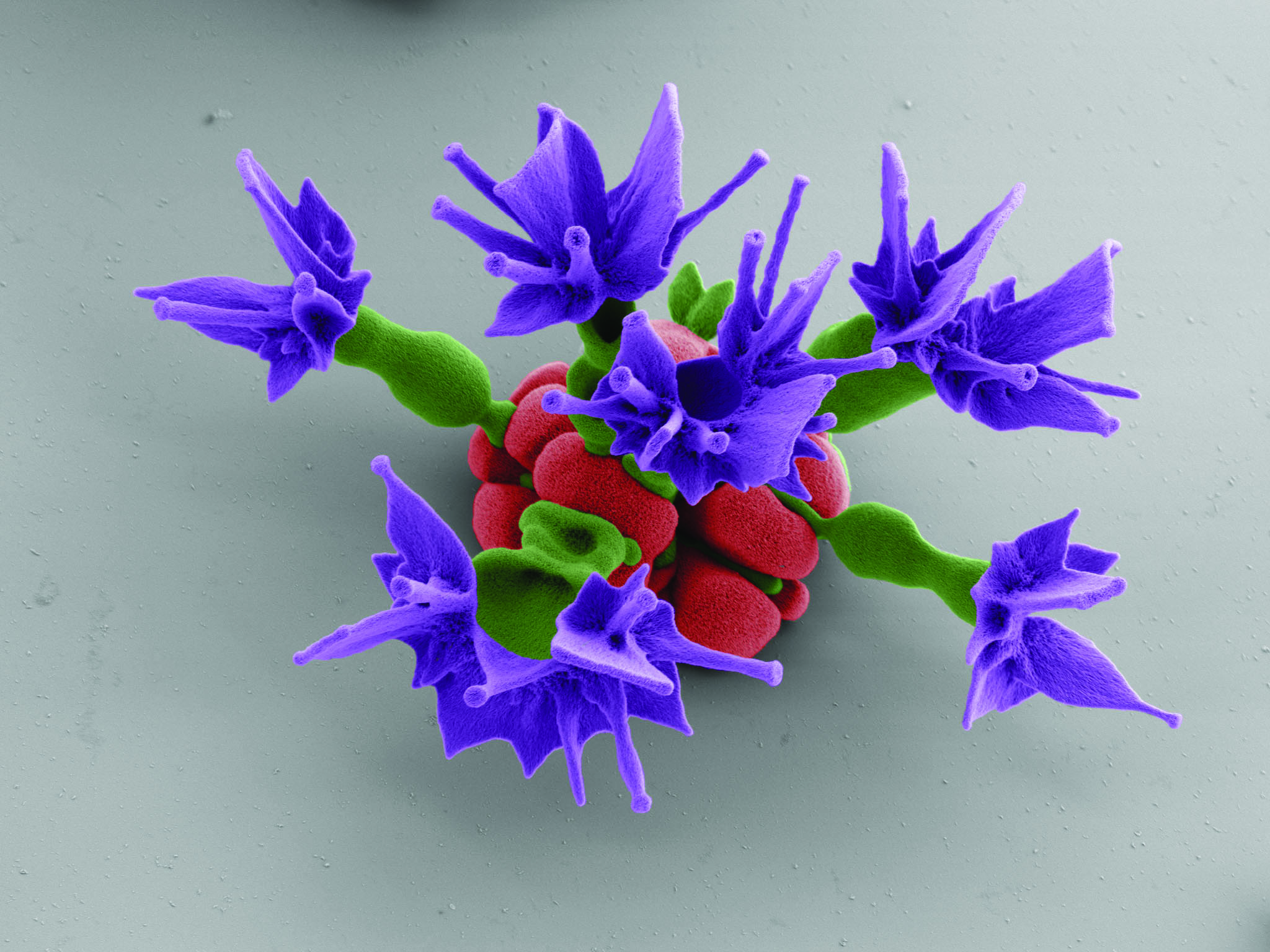

Synthetic crystal flowers sculpted at the nanoscale using timed interventions in molecular self-assembly, 2013; Joanna Aizenberg (Russian, born 1960); Scanning electron micrograph image with false color

COOPER HEWITT: Was the Wyss Institute always meant to be a place for collaboration across disciplines?

DON INGBER: Yes. Absolutely. The original challenge was to envision the future of bioengineering across Harvard and all of its affiliated hospitals. If you look back on bioengineering over the last fifty years, enormous advancements were made by applying engineering principles to solve medical problems—dialysis machines, respiratory ventilators, endoscopes, stents, and pacemakers are just a few examples. During the past ten to twenty years there’s been a breakdown of the boundaries between living and nonliving systems, and many of us were already collaborating across these different fields. We realized that we’d uncovered enough about how nature builds, controls, designs, and manufactures from the nanoscale up so that we’re now at a point where we can leverage biological design principles to develop new engineering innovations—this is what we termed “biologically inspired engineering.”

CH: What sets Wyss Institute apart from other cross-disciplinary academic labs?

DI: The Institute’s vision is that breakthrough discoveries cannot change the world if they never leave the laboratory. It was designed to confront the challenge of translating technology advances across the academic-industrial interface. The organizational model we’ve developed is specifically designed to overcome many challenges that have held back technology innovation and intellectual property generation in the past. It ensures efficient translation of discoveries into products that enter the marketplace in order to improve human health and enhance sustainability.

CH: Joanna, can you talk about your work and how collaborations across disciplines factor into your process?

JOANNA AIZENBERG: Absolutely. When I joined Harvard, one of my initial ideas was to establish collaboration and interaction between the School of Engineering and the School of Design. Work on environmental issues was happening at both schools, but separately—not in any joint or common way, so that we might teach our students or think about these problems across disciplines.

CH: What were some of your first impressions working with and observing these two disciplines in collaboration?

JA: Architects and designers are working with materials, and engineers are creating the materials. The very innovative collaborative work was really being done outside of our own comfort zones. We speak different languages and teach students differently, so the only way that we can move effectively is through collaboration, thinking outside the traditional box.

This early work led to the establishment at Harvard of a new degree—Masters in Design Engineering (MDE)—where half of the classes are in engineering sciences, in the School of Engineering, and the other half from the School of Design. The MDE engages a new generation of people who are thinking about design from a materials’ properties perspective, not only aesthetically, but how we might improve practical and functional aspects that address environmental or energy-related questions.

(left) Portion of the light-guiding, ultra-strong skeleton of a Glass Sea Sponge, 2003; Joanna Aizenberg (Russian, born 1960); Photograph. (right) The Gherkin, 30 St. Mary Avenue, London, United Kingdom, 2003; Designed by Foster + Partners (London, United Kingdom, founded 1967).

CH: What obstacles might arise along the way?

JA: There are quite a number of obstacles. In sciences and technologies, every community has its own sources of support. Often there is an inability to find support for students and teams because the parameters for research grants aren’t aligning with these new team structures. It was issues like these that led to the development of the Wyss Institute structure of supporting paths beyond research and publishing, to patents and commercialization in the market. The Wyss model brings an advanced technology team into the mix, therefore introducing a new focus for the work.

Another obstacle arising out of the cross-departmental teams is where to do the work. Development of large-scale projects, such as designing and fabricating prototypes, can be done at the School of Design, but they’re unable to do things at a small scale (microscopically). Today, nearly every material we make has to be designed from the very small scale up and for that, you need facilities for microscale and nanoscale fabrication. Wyss Institute–supported labs facilitate this joint work, providing the required technical support and facilities.

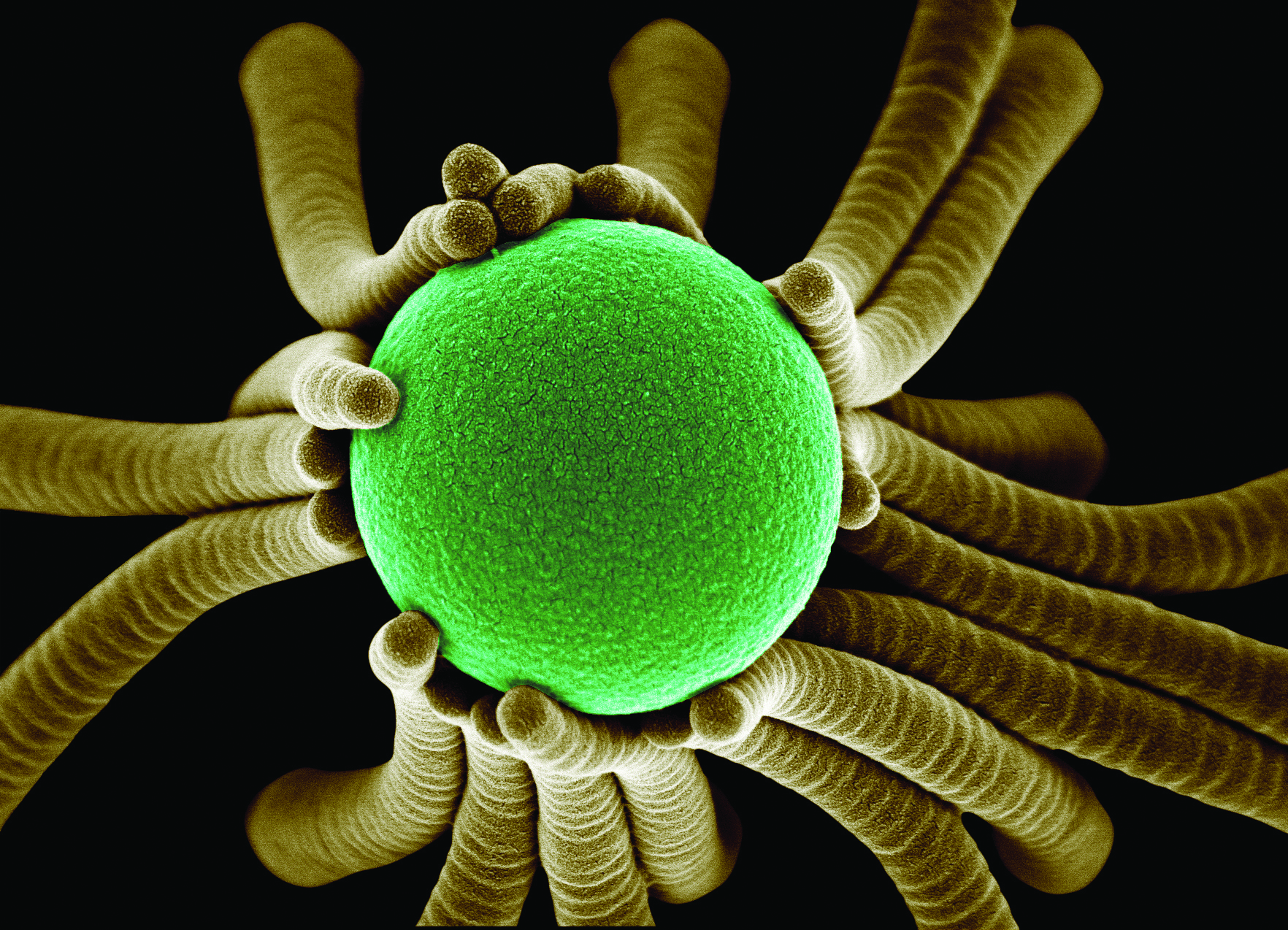

Synthetic cilia demonstrating the principle of self-assembly around a spherical nanosphere, 2009; Joanna Aizenberg (Russian, born 1960); Scanning electron micrograph image with false color

CH: The Institute is designed to bring fundamental and applied research to serve a broader purpose. How does this happen?

JA: It runs like a startup company. The advanced technology team are people working directly with scientists to make sure that a project we choose is not just a good idea, but that it can be brought to a prototype within a well-defined time frame. A good example is my Slippery Surfaces project, which was one of the first companies that was launched through the Wyss Institute. The first paper publishing our discovery came out in 2011 and the new company, which later brought it to market, was launched in 2013. That’s a really short time. The business team quickly assesses needs for the product, market climate, and financials, so that the researchers can move on from work showing promise at the fundamental science level and simple prototypes to more doable, practically important, and scalable projects.

CH: What does the assessment model look like?

JA: Wyss Institute runs the team work through what’s called the Validation Project. Concepts have one to two years to be brought to a level where they can graduate and become commercialized. We came up with an idea for a new material—a butterfly-inspired coating—that can clean air from volatile compounds at room temperature. The ability to purify contaminated air has value well beyond a publishable piece of work, as it also applies to catalytic converters. Catalytic converters ensure that the exhaust that comes out from our cars is not polluting the environment, and our project addresses recent serious problems with a number of car manufacturers that brought inefficient catalytic converters to market.

My group developed the idea, patents were filed, and through Wyss were shared with the designers. At the end of the validation phase, a company was launched. The new company will commercialize these catalytic materials for a whole range of applications, but primarily for air purification from volatile organic compounds, including purification of exhaust from vehicles. It’s a really nice path from discovery and patent to validation and launch.

Slippery Surfaces, the technology I mentioned earlier, is now being applied to a whole new area, different from what the company was launched on, which was the technology that prevents ice formation on airplane wings. Now SLIPS are being applied to a paint used on surfaces where barnacles and mussels accumulate, such as on bridges, ships, boats. The technology will hopefully lead to a new generation of coatings that will prevent biological fouling and its accumulation coming from the ocean. These coatings will not leach toxic chemicals into the environment that kill the living creatures, but will rather prevent their attachment by completely different means. This technology will positively impact our environment improving fuel use and the associated energy penalties of the current problems with bioaccumulation on marine vehicles.

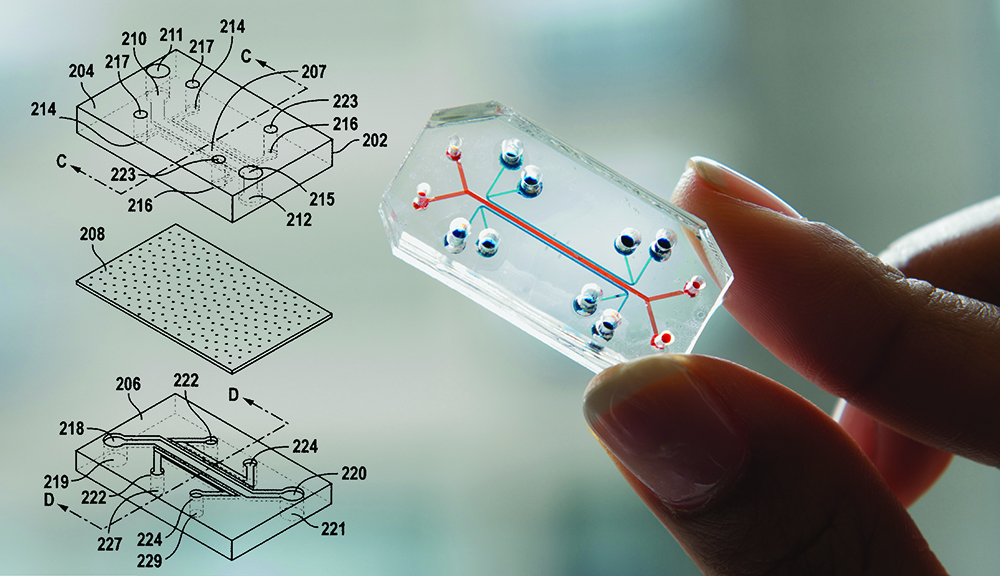

Microfabricated Organ-on-a-Chip device that can replace animal testing when lined with human tissue cells, 2009; Donald E. Ingber (American, born 1956); Photograph of patent and device

CH: Why do you see such resonance in collaborations involving materials science, technology, and design?

JA: The interactions of designers with scientists are essential for thinking about how a new generation of adaptive materials—materials that can change their properties in response to the environment—is considered across the length scales, from nanoscopic to the practical macroscopic scale. Our work isn’t necessarily mimicking a specific function that nature has evolved but rather our work is bio-inspired, in a sense that it creatively combines lessons from various organisms that can be applied to solve specific design challenges.

Nature can only work with proteins and subsets of very weak materials. We have cements and steels. Our materials are better. But they are not as “smart.” We can now develop the whole range of manmade materials and provide them with smartness, designing them with the lessons from natural materials. I think this is where the future in design lies.

Joanna Aizenberg, PhD, is the Amy Smith Berylson Professor of Material Sciences at Harvard John A. Paulson School of Engineering and Applied Sciences, a Professor of Chemistry and Chemical Biology in the Department of Chemistry and Chemical Biology, and Co-Director of the Kavli Institute for Bionano Science and Technology.

Donald E. Ingber, MD, PhD, is the Founding Director of the Wyss Institute for Biologically Inspired Engineering at Harvard University, the Judah Folkman Professor of Vascular Biology at Harvard Medical School and the Vascular Biology Program at Boston Children’s Hospital, and Professor of Bioengineering at the Harvard John A. Paulson School of Engineering and Applied Sciences.

Wyss Institute Selects is on view at Cooper Hewitt through May 4, 2020. This article was originally published in the Summer 2019 issue of Design Journal, Cooper Hewitt’s biannual magazine.

4 thoughts on “Taking Lessons from Nature”

Timothy Lyall on February 25, 2022 at 12:16 pm

Nice post that made me think more about nature, thanks.

Joanne on May 30, 2023 at 2:38 pm

Very interesting article!

Jose Miller on July 5, 2023 at 9:43 am

nice

Murray P. Borges on August 2, 2023 at 9:22 am

Nice post, I’m excited about how the world around can change.